Technical Expertise

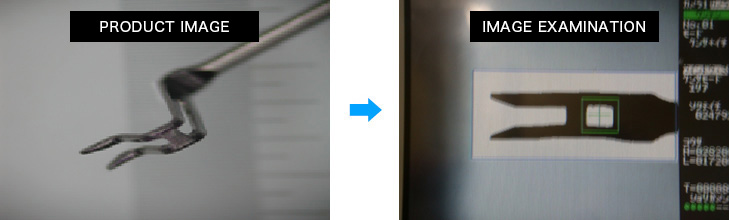

Making full use of knowledge over about 100 years of company history,

we are proposing different processing that have changed our perspective.

we are proposing different processing that have changed our perspective.

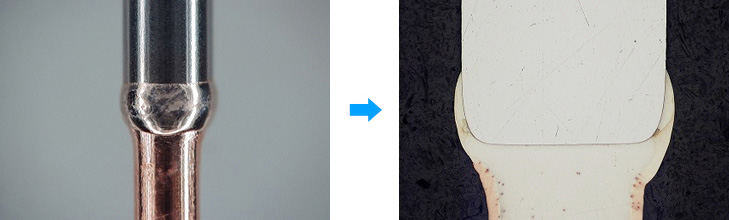

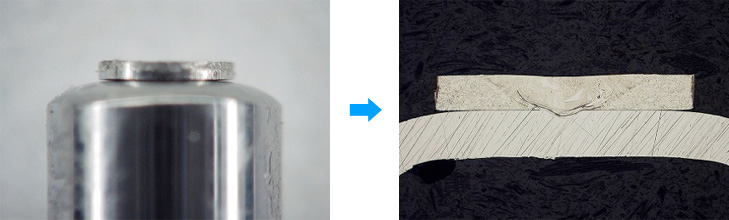

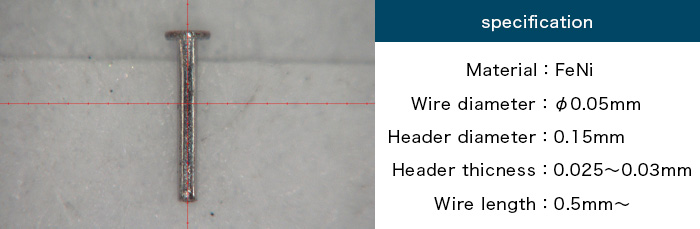

| entry/Product classification | explanation | cut lead | Fine cut lead |

| Reference design | Shape and appearance of the cut | Cut the wire | Cut the wire in a special way |

|

|