We are a manufacturer of precision microfabrication of metals.

Leads for electronic components

Leads for various lamp electrodes

Leads for HID lamp electrode for automobiles

Crystal oscillator parts

Leads for exhaust gas oxygen sensor for automobiles

Leads for airtight terminal for sensor

Parts for snaps for fishing gear

Leads for capacitors

Leads for gas sensor electrodes

We support our customers from a different perspective than conventional processing methods by making full use of the multiple technologies we have cultivated over many years.

contact

Tel.+81-868-35-3770

The latest Technology

Our Best Recommended Technique

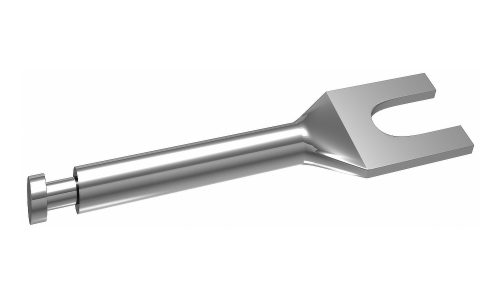

In order to respond to the increase in the number of terminals and narrow pitch as semiconductor chips become more highly integrated, we have developed ultra-micro forged pins for connection terminals using wire materials with a wire diameter of 0.05 mm and our proprietary micro-header processing technology. We have developed ultra-micro forged pins for connection terminals using our proprietary micro-header processing technology to meet the increasing number of terminals and narrow pitches.

Since the material flow during the forging process can be controlled in 1 micron increments, we are able to handle T-shaped pins and other complex shapes, and have achieved extremely stable quality.

This product can be applied to Cu pillars for semiconductor chips and medical devices.

More

Technical Expertise

Making full use of knowledge over about 100 years of company history,

we are proposing different processing that have changed our perspective.

-

– Welding processing –

◯Resistance welding two pieces(1 spots welding) -

– Forming processing –

◯Forming lead ◯Anchor lead ◯Ag solder -

– Forging processing –

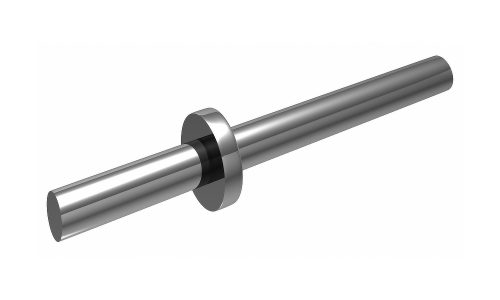

◯header lead ◯middle flange pin ◯two stages flange pin ◯minimal forging -

– Fine cut processing –

◯cut line(regular cut, fine cut) -

– Composite processing –

◯Welding+Stamping ◯Welding+Forging ◯Forging+Brazing ◯Forging+Cutting

Reduce Cost

Contact Tsuritani if there are any processing cost problems

Reduction in cost is possible through our various techniques that we have cultivated over many years.

More